LIXIL’s manufacturing plant in Hemer

Where the GROHE story started

In Hemer, in the peaceful and relaxing surroundings of the ‘Märkisches Sauerland’, the success story of GROHE, now part of the international LIXIL family, begins: In 1936, following the death of the founder of the ferric hardware factory Berkenhoff & Paschedag (dating from 1911), Friedrich Grohe was asked to step in.

The young entrepreneur was a man of action: Grohe immediately seized the opportunity presented by this location near the highly industrialized Ruhr area with both hands.By accepting the challenge and acquiring the factory, which he renamed ‘Friedrich Grohe Armaturenfabrik’ in 1946, making it an even more personal affair, he wisely chose the starting point for developing his vision of a new business model.

From that moment on, the Hemer plant grew into a wholesale business for bathroom fixtures – and the small town in North Rhine-Westphalia surrounded by nature developed into one of Europe’s leading hubs for fittings and premium faucets.

A technological hub in a scenic environment

Since then, the LIXIL plant in Hemer has evolved into a global competence center for premium faucets and cartridges. As of 2021, 600 employees are working at the plant, producing more than eight million items.

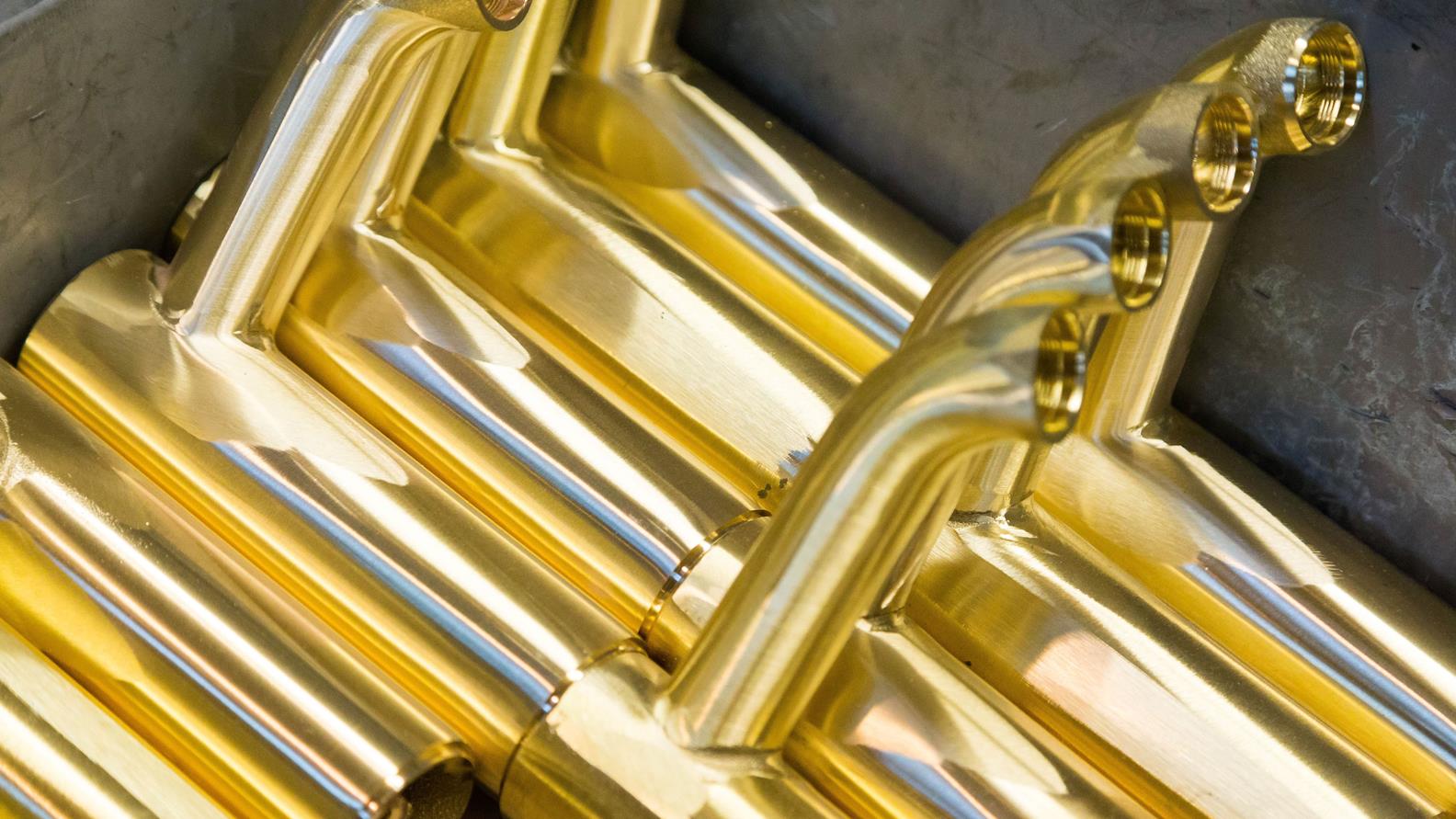

The LIXIL plant in Hemer is home to the global R&D lab for fittings, which set new standards for the whole sanitary industry by embracing the still-emerging technology of 3D metal-printing, resulting in 3D products of dazzling precision, lightness, and modern elegance.

Where cutting-edge digital technology meets craftsmanship

All premium products manufactured at the Hemer LIXIL site, such as faucets and thermostats, are deeply rooted in the tradition of solid and durable craftsmanship, but also take the future of bathroom design to exciting new places.

And with the GROHE Icon 3D collection, Allure Brilliant Icon 3D, and Atrio Icon 3D, the impossible has become cutting-edge reality.